Facility Overview:

The Vehicle Design Lab is equipped with state-of-the-art tools, equipment, and software necessary for vehicle design and fabrication. The facility encompasses designated areas for design workstations, fabrication workshops, testing tracks, and storage spaces for vehicle components and prototypes. Additionally the lab also has additional equipment like Fein- Pipe Notch making machine, Power tools, TIG welding machine, etc. which helps the students to work more smarter and faster to meet their project deadlines.

1. Design Phase:

Students engage in conceptualizing and designing vehicles using Computer-Aided Design (CAD) software. They work on creating detailed 3D models that encompass aspects such as Driver Ergonomics, aerodynamics, structural integrity, and performance optimization by using the software like Solidworks, CATIA, Hypermesh, Ansys, Lotus shark, MATLAB-Simulink, Carmaker, etc.

2. Fabrication Phase:

After finalizing the designs, students move on to the fabrication phase. The lab is equipped with machinery such as Pipe Notch making machine, 3D printers, welding stations, and assembly areas where students fabricate vehicle components and assemble prototypes.

3. Testing Phase:

The lab features a dedicated testing area at South campus of Sri Vishnu Educational Society where students evaluate the performance of their vehicles. This includes dynamic testing on test tracks for assessing speed, handling, and durability. Additionally, students conduct static tests to evaluate structural integrity and safety features. This a very unique facility named- Vishnu ATV & Gokart Track which is spread over 2.5 acres of land.

4. Motorsport Vehicle Projects:

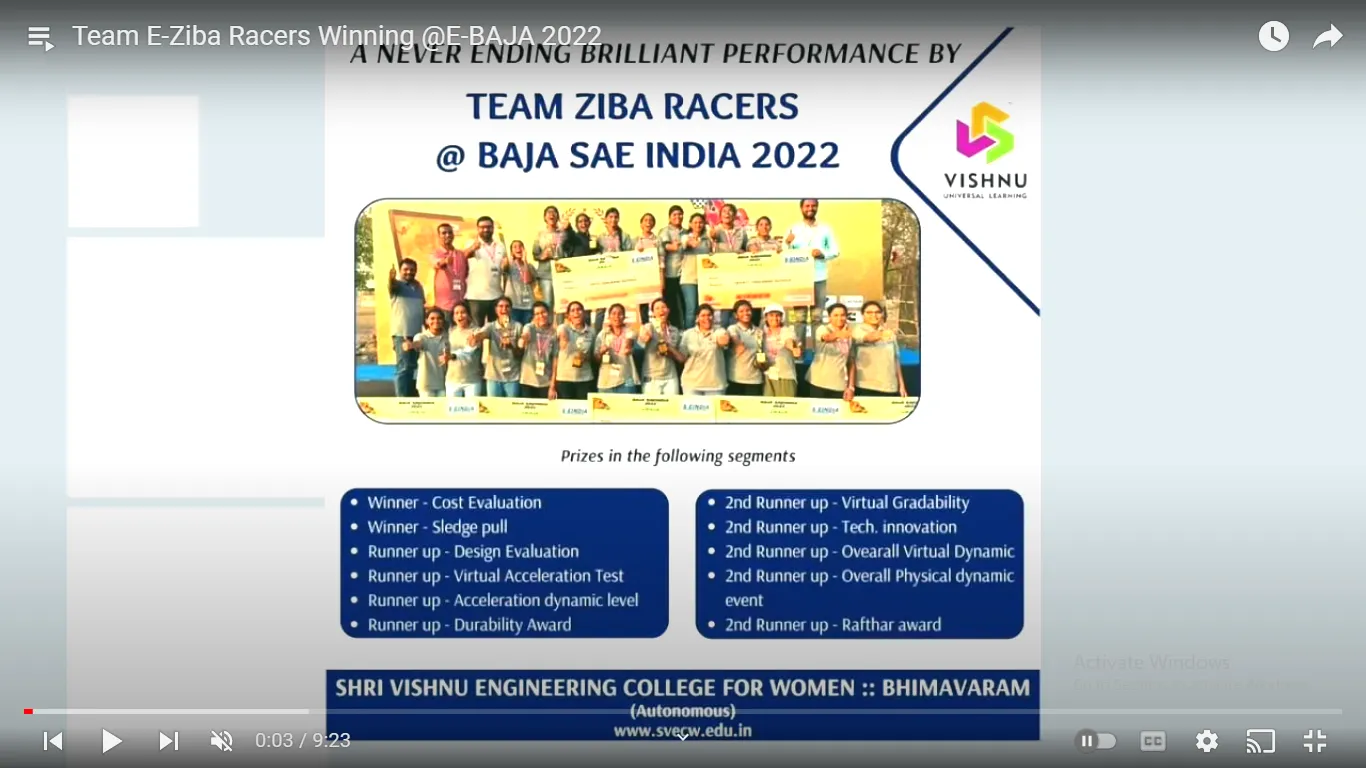

Students undertake projects focused on designing and fabricating motorsport vehicles such as Formula SAE cars, Baja off-road vehicles, Gokarts and electric race cars. These projects involve competition participation where students showcase their vehicles and compete with teams from other institutions like IITs, NITs, Private Universities etc. We have a record of being top team in SAEINDIA BAJA for last 05 continuous years.

In addition to motorsport vehicles, students also work on designing and fabricating campus utility vehicles. These projects focus on developing efficient and sustainable vehicles for campus transportation, maintenance, and logistics purposes.

- Electric Cargo Vehicle – The vehicle is completely fabricated in-house with 5kW PMSM motor and 72V power supply having a battery capacity of 7.2Kw. The vehicle is currently used for in-campus Utility Purposes with a maximum payload capacity of 950Kg.

- Electric Gokart – Design and Fabrication is done in-house at college and the Vehicle is used for different National motorsport competitions and has bagged a series of awards since 2019. Gokart is having a 2kW motor nominal power and battery pack of 2.88kW.

- Electric Bike for camps Utility – A double seater capacity electric bike is designed and fabricated at college camps with a hub motor of 1kW capacity and is used for in-campus utility purposes and having a range of 40km at normal Indian temperature conditions.

- Electric Bicycle for Railway Track Inspection (Gangman Electric Cycle) – We have designed and Fabricated India’s First Gangman Electric Cycle which is used for Railway Track Inspection by Gangman and the project is successfully tested and donated to Bhimavaram Town Railway station. For the same we have also received an appreciation certificate from Railways.

- Fish feed electric boat (consultancy project for Uno feeds company – Komarada, Bhimavaram)- We have designed an electric propulsion system for UNO FEEDS Company which is a Fish Feed Company at Komarada, Bhimavaram. The project is successfully tested at the company location.

- Campus Shuttle Solar Vehicle – We have modified a 11 Seater Campus Shuttle BEV(Battery Electric Vehicle) into a Solar-Electric Vehicle which can be charged while it’s running.

- Retrofitment of TATA ACE campus vehicle – We are Retrofitting an existing TATA Ace vehicle with L5 kit for Electric Vehicles and the vehicle is fitted with 10kW PMSM motor and battery pack of 10.8kW. The vehicle is having a payload capacity of 1.5Tons.

- Hybrid Activa – We have converted an existing Honda Activa to hybrid vehicle where the vehicle has 01Kw of motor and 1.5kW batter pack reaches a maximum speed of 45Kmph with 02 seating capacity and range of 40 km in a single charge.

- Electric Splendor – We have converted an existing Hero Splendor to electric vehicle where the vehicle has 1.5Kw of motor and 3.2kW of Batter pack reaches a maximum speed of 73Kmph with 02 seating capacity and range of 90 km in a single charge.

- Retrofitment of Maruti ECCO campus vehicle – We are Retrofitting an existing Maruti ECCO vehicle with L5 kit for Electric Vehicles and the vehicle will be fitted with 10kW PMSM motor and battery pack of 09 kW. The vehicle is 08 seater capacity with max speed limited to 30kmph and range is 60km in s single charge.